Enter your shipment number.

What We Do

End-to-end supply chain management with flexible logistics solutions for your evolving business needs.

Ocean

Air

Contract Logistics

Project Logistics

Packaging Solutions

Raw Materials Management

Road

Customs Brokerage

4PL

Supply Chain Visibility

Ocean

Providing customers with flexible FCL and LCL services throughout the world.

Our friendly ocean freight team’s flexible carrier contract portfolio allows us to design logistics solutions based on your business requirements: volume, weight, packaging, pricing, transit time, or handling conditions.

Air

When OIA Global was founded in 1988, we exported perishables from the Pacific Northwest under the name Oregon International Air Freight.

We take pride in our air cargo roots! Today we manage air freight shipments in more than 100 countries with 500+ different types of cargo. With 30+ years of global logistics experience, we know what it takes to deliver when time or capacity is scarce.

Contract Logistics

We handle 260+ billion units annually.

OIA Global’s contract logistics segment has the resources and expertise to build impactful solutions throughout all phases of your distribution logistics network. We work to align our contract logistics solutions with your company’s values, product type, and customer base.

Project Logistics

Our heaviest shipment ever transported was a 600 MT pile hammer used to install offshore wind turbines.

Complex logistical movements require careful staging, sequencing, and coordination. OIA Global’s project logistics team doesn’t just overcome problems—they anticipate them. Our team recognizes that creativity and adaptability are critical to any plan, whether it be power plant equipment or sustainable energy infrastructure.

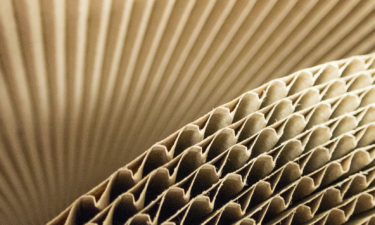

Packaging Solutions

We complete 350+ innovative packaging projects every year.

Our award-winning packaging solutions and account management team guides customers from the conceptual stage toward polished, supply chain-ready product packaging. Our packaging is built to withstand harsh transportation, warehouse, and storage conditions. We impact the entire packaging lifecycle by optimizing space and materials and delivering sustainable designs that brands and customers love.

Raw Materials Management

We manage order processing for more than 775,000 units of materials every hour.

With a comprehensive supplier base of raw and recycled materials, we provide your business with automated order processing to allocate material orders to the right production facility.

We buy and transport materials to meet customer demand in compliance with your manufacturing and corporate social responsibility requirements. We also practice sustainable sourcing to bring your business vision to life in an ethical and efficient way.

Road

With a trucking carrier network of >3,000 vetted providers, OIA’s road freight specialists will match your freight to the right flatbed every time.

OIA’s comprehensive road freight services provide your business with specialized logistics solutions, allowing you to meet customer demand or build distribution programs wherever they’re needed. Our trucking logistics team knows how to combine transport execution and transport management to move your goods with high service reliability.

Customs Brokerage

We offer solutions designed to maintain efficient, compliant processes while providing full visibility every step of the way. Our dedicated team of brokers and compliance specialists delivers expert oversight and actively works to reduce risk, so your cargo keeps moving.

4PL

We manage 20+ ocean carriers, 30+ loading sites, and 150+ delivery sites for just one customer.

Imagine if your global logistics operations were managed by a dedicated business partner who assumed full responsibility for your supply chain management and performance. As an extension of your business, we partner with you to assess, manage, and optimize your supply chain’s numerous touchpoints, providing complete business intelligence and a single source of truth.

Supply Chain Visibility

OIA Connect customers save up to 1.5 hours of work per week.

OIA Global offers end-to-end cargo track and trace through an electronic suite of supply chain visibility tools led by our award-winning product OIA Connect. This real-time, easy to use cargo tracking tool links all the various touchpoints in your supply chain: suppliers, carriers, customs authorities, and final customers.